Payment Methods:

- Low Minimums of 100 Boxes

- Free Die and Plates

- Competitive Pricing

- Customized Sizes & Styles

- Fast Turnaround Times

- High Quality Offset Printing

- Free Design Support

- Free Shipping

Engage our expert

+1 (201) 510-1994

Payment Methods:

Custom noodle boxes are often made of sturdy materials such as cardboard, kraft paper, or corrugated fiberboard and are intended to retain and protect fresh, dried, or cooked noodles. They come in a variety of sizes, styles, and patterns to fit different types of noodles, including ramen, udon, soba, and even pasta meals. The customization possibilities enable firms to add distinctive elements that reflect their brand’s ethos and appeal to their target demographic.

Customization Options.

CMYK, PMS, No Printing

10pt to 28pt (60lb to 400lb) Eco-Friendly Kraft, E-flute Corrugated, Bux Board, Cardstock

100 – 500,000

Gloss, Matte, Spot UV

Die Cutting, Gluing, Scoring, Perforation

Custom Window Cut Out, Gold/Silver Foiling, Embossing, Raised Ink, PVC Sheet.

Flat View, 3D Mock-up, Physical Sampling (On request)

6-8 Business Days, Rush

We have a wide range of boxes, select one or write for others.

Complete our quote form to receive a customized quote from our product specialists.

After getting the awesome price, just say print it!

We will help you with completely custom dielines according to your needs

Collaborate with our design experts for you top notch artwork

We will send you 3D mockups of your print ready packaging

After approving everything, sit back and relax, while we produce

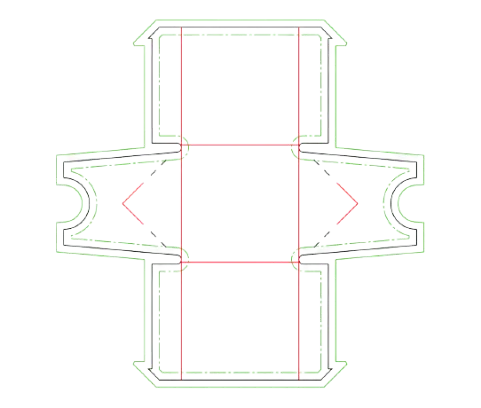

Indicates the cut at its final size. Important artwork and text should be placed at least 0.125 inches inside of the cut line.

Perforation line refers to paper that is punched with very small holes to allow the paper to be torn and folded easily.

Indicates where the bleed line is located. Any artwork which goes to the cut line should be extended to the bleed line to get a seamless print.

Indicates where the product is to be folded.

Indicates where artwork and text should safely be placed inside. As an industry standard, all artwork should at least be placed 0.125 inches away from the cut line unless your design is intentional.

i Box Factory exceeded our expectations with their modern packaging for our gadget. The quality is top-notch, adding a professional touch. The team was responsive and made the whole process smooth. I highly recommend them!

i Box Factory transformed our bakery’s packaging with their custom boxes. They’re not only beautiful but also durable, keeping our pastries fresh. We've received so many compliments from our customers. The team’s attention to detail and service were outstanding!

i Box Factory provided us with top-quality packaging for our medical products. Their precision and adherence to regulatory standards were impressive. The team’s expertise and efficiency ensured everything was perfect. We’re very satisfied and recommend them highly!

The custom packaging from i Box Factory elevated our boutique’s image. The boxes are chic and perfectly match our brand’s style. The entire process was seamless, and our customers are impressed with the new look. We’re thrilled with the results!